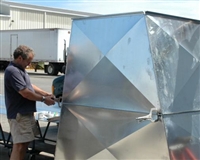

Sheet Metal Duct Fittings

All of our fittings are designed by Harry or Brett, entered into the computer on the plasma table and custom built to meet the specific needs of your home or business. Our state-of-the-art sheet metal shop produces the most cost-effective and reliable metal fittings on Nantucket.

This was an unusual duct system. The home owner wanted to finish the basement at some point down the road and wanted all the height they could get. It's hard to see, but the first floor is bi-level. This called for some interesting fittings, which had to be radius, not square, for good quiet airflow.

2"x8" to an 8"x22" to an 8"x22" Goldberg (or reverse elbow) to another 22"x8" to an 8"x22" to the drop.

(View 1 of 3)

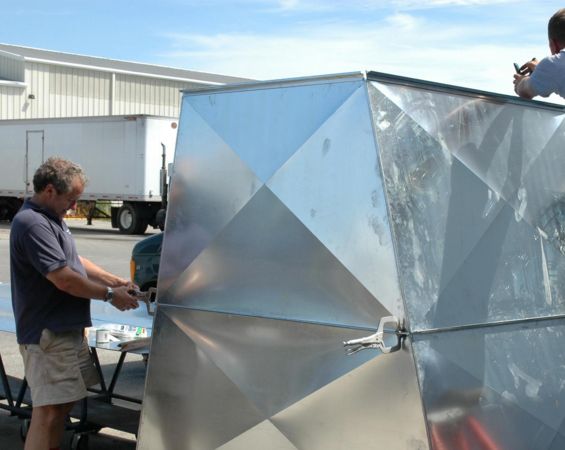

We needed to make this fitting in order to eliminate square corner turns. If you look carefully at it, you will see that air entering at the top is 8"(the side you see) by 20 (the bottom). Air exits the elbow with the dimensions twisted 90 degrees and is flat on the back side to hug the airhandler. Smooth and quiet airflow.

(View 2 of 3)

This one is tough to describe. It accommodates the bi-level first floor while maintaining good quiet air flow by avoiding right angle fittings. Hence the horseshoe-shaped fitting you may have noticed bottom-center.

(View 3 of 3)

Here is a custom tee-fitting starting with 20"x18" at air handler (bottom) then to 8"x10" heading to the right and 8x12 headed to the left. The tee is flat on back to hug the structural beam.

heating system. Flexible duct runs should be kept to a minimum to maintain proper air flow and sufficient CFMs.

This furnace and air conditioning system is installed in a knee wall. The elbow in the background is designed to fit the roof line: a full radius would hit the ceiling. The duct to the right is insulated 26-gauge galvanized sheet metal pipe which becomes flexible duct in the last 4 feet to meet the supply boot buried under the plywood.

Here is a 20"x20" elbow, offsetting down 4" and transitioning to 8"x22" to meet space constraints and smooth out the airflow. This takes a little more work to design and build, but it is better than 14" flex running off a square fiberboard box taped to the air handler.

Here's a good example of custom fittings. This system has two zones and the ductwork had to cross in order to reach each zone with the proper amount of air flow.

The plumber thought he had us here, but our duct just misses the PVC elbow and 3" drain line thanks to this 20"x8" to 8"x20" fitting (with a 4" offset, of course.) Time to fabricate 3-4 minutes to cut and 15-20 to assemble. Time was, metal duct systems averaged double fiberglass, but with the automated machinery we have today, we are very competitive in price.

Here we used four fittings here to get over a steel beam. We started with a 30 degree ell off the tee to a 60 degree elbow to a 4" offset to an 8" offset... This one required a bit of thought.

This is a 36" roof flange on a 8/12 pitch for Grey Lady Marine. The little person is our quality control expert. See the next photo (or head over to Arrowhead Drive) for a view of it installed on the roof.

The exhaust system for Grey Lady Marine sits on top of our roof flange fitting, which makes the roof penetration.

This custom wine cellar installation is a great example of how to control temps without being obtrusive. The two grilles are sized to be nearly silent and we can keep the temp within 1 degree of set point.

Now here is a transition left 7" and down 4", with an opening of 36"x44" at one end and 52"x48" on the other. It was made in 8 pieces and bolted together later. It is now an intake fitting providing make-up air for the Grey Lady's furnace.

We made this exotic elbow to a split tee fitting to stay flush with the bottom of the steel beam. Notice how the duct work can be brought over the beam yet still respect the beam height for future boxing. With a little extra thought, ductwork doesn't have to compromise ceiling height.

This was interesting. My good friend Dick Savory... "Can we put the equipment in this space, here". There are three air handlers, three duct systems and a wall hung boiler in "this" very small space. Three-dimensional chess may have been easier.